Application

Thermostop is used as thermal separation between wall fixture and supporting base. It can be mounted through a simple through-hole assembly.

The typical areas of use are:

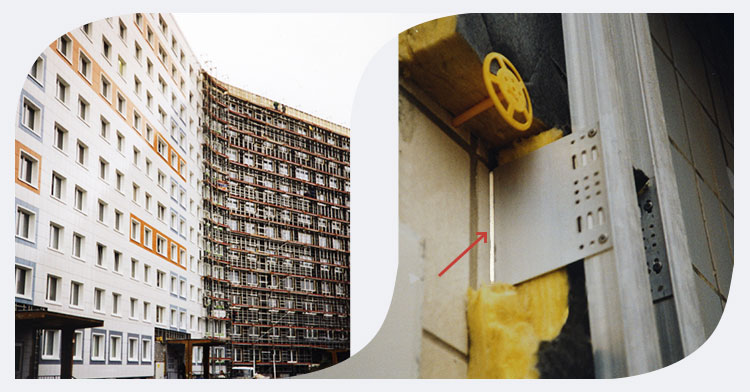

Thermally separated anchoring points with windows (Landeslabor Berlin)

Rear-ventilated facade

External wall cladding is mounted to the inner shell through support rails, consoles and anchoring. The consoles penetrate the insulation, which allows heat from the inside to escape through the wall fixtures. At the same time, low temperatures during winter can lead to the cooling of the wall. This increases heating costs and emissions.

With growing requirements for energy efficiency and increasingly thick insulation, the issue of thermal bridging in the form of selective heat loss becomes more prominent.

To meet the Energy Saving Ordinance (EnEV- German regulation for energy saving), these energy losses have to be taken into account.

A rear-ventilated facade in Berlin Lichtenberg with a Thermostop placed between wall and aluminium sub-structure to reduce heat loss.

Additional to its insulating quality, Thermostop serves as corrosion protection. It inhibits the build-up of condensation water during winter, which would otherwise form between the warm base and cold wall fixture.

Thermal conductivity of materials

The usual metal sub-constructions of rear-ventilated facades create serious thermal bridges at the anchor points, leading to a higher U-value of the wall construction.

Consoles / Sub-construction

| Aluminium | 200 W/mk |

| Steel | 60 W/mk |

| Stainless steel | 15 W/mk |

Materials / Insulation

| Compressed paper | 0,20 W/mk |

| Polypropylene | 0,20 W/mk |

| Hard PVC | 0,17 W/mK |

| Wood | 0,14 W/mk |

| Thermostop | 0,08 - 0,09 W/mk |

Thermal insulation in relation to material thickness

Increasing insulator thickness leads to increased thermal insulation although the increase is not proportional. Tests conducted at the Technical University of Berlin [1] showed the following savings potential:

Isolator-

thickness

5 mm

10 mm

15 mm

20 mm

25 mm

30 mm

Percentage improvement

in thermal insulation

19,5 %

25,0 %

28,0 %

29,9 %

31,1 %

32,0 %

Recommendation

When taking the relative improvement in insulation, the static characteristics, and the costs of thicker material into account, a Thermostop of 5-6 mm produces the best cost-benefit ratio.

Learn more about Thermostop

[1] Prof. Cziesielski "Wärmebrücken im Bereich der Verankerungskonstruktionen", Baumesse München, 15.01.97